From a young age, Wuji Huang has been driven by a curiosity to understand how things work. As an undergraduate at Fudan University in Shanghai, China, and later as a master’s student at the University of Florida, Huang majored in materials engineering, focusing on understanding how engineering materials function in industrial applications.

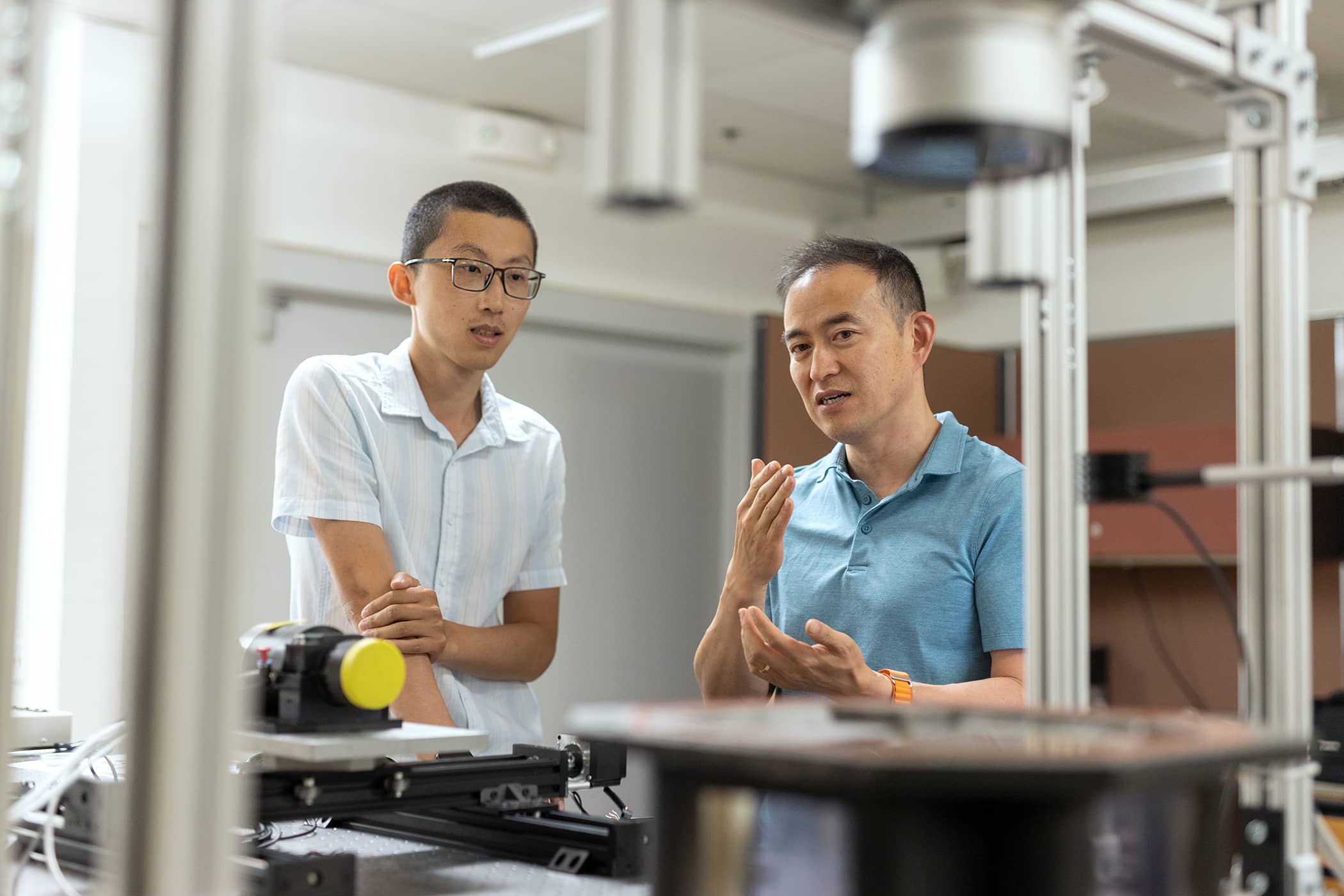

Huang carried this passion to the University of Iowa, where he joined the Mechanical Engineering PhD Program in the fall semester of 2019. Under the guidance of Professor Hongtao Ding, Huang developed a groundbreaking laser technology capable of processing large-area superhydrophobic surfaces for metals—an advanced and challenging area in the field of laser engineering.

“This might sound niche, but this work is important for a wide range of everyday applications, such as preventing corrosion and reducing friction to make transportation more efficient,” says Huang, who defended his dissertation, Quantitative Analysis and Applications of Laser-Induced Superhydrophobic Metal Surfaces, in March 2024. His PhD research resulted in seven first-author journal papers and two pending patent applications.

Innovative laser research

Huang’s research relied on a method called nanosecond laser-based high-throughput surface nanostructuring, pioneered by Ding’s research group. Huang focused on treating large-area metal surfaces with high processing efficiency for practical applications, isolating and quantifying the effects of topography and chemistry on wetting properties.

The laser altered the 3D-printed metal surface’s topography, causing it to become hydrophobic and allowing water to flow along a designed path. This process can create anti-corrosion barriers and design efficient water-collecting surfaces.

“While many research fields are related to fluid-solid interaction, we wanted to manipulate how water flows,” Huang says. “In a heat exchanger, you have metal pipes with water or fluids running inside them. You want to control how those fluids flow to achieve higher heat exchange efficiency.”

This heat exchange efficiency is relevant in aerospace engineering and automobile construction.

“A plane’s wings are constantly interacting with the air, which is like a fluid. You want to manipulate that to reduce friction,” Huang says. “You can also reduce friction when designing the surface of a car’s shell.”

“Electric vehicles have batteries, and the cooling components of the batteries can be optimized to improve cooling efficiency and prevent overheating.”

Huang received the 2022 Ray L. and Edna P. Sweigert Memorial Fellowship and the Graduate College Post-Comprehensive Research Fellowship in 2022 and 2023, respectively, from the University of Iowa. He also spent one semester working as a research intern for General Motors.

Professor Ding says his lab addresses the fundamental challenge of scaling up a laser process for the manufacturing industry.

“In order to make this happen, innovation and interdisciplinary research are crucial,” Ding says. “Our lab is not equipped with an industrial laser; we just have a simple lab-grade laser. Thanks to the new manufacturing science, we have increased the process speed by about 1,000 times. The key is integrating laser technologies with surface chemical modification technologies. The chemicals we use are widely available, but combining the chemical process with a laser process is new.”

The lab’s initial experiments have produced positive results for the future.

Resolute researcher and teacher

While earning his PhD, Huang made a significant impact on the Mechanical Engineering program.

“Huang is a very dedicated researcher,” Ding says. “In the laser research community, there are similar interests from various groups and universities. We ensured that his PhD work is unique.”

Alongside his research, Huang served as a lead teaching assistant for manufacturing processes, modeling, and simulation courses for eight semesters. He also mentored multiple undergraduate and high school student researchers.

Huang has since joined industry for the research and development of new lubricants for engine surfaces.